As a 10-year experienced LED strip manufacturer with BSCI certification and products certified by CE, RoHS, TUV, and UL , GEROLUX provides high-quality lighting solutions for various applications. Among our extensive product lineup, IP20 non-waterproof (bare PCB) LED strips and IP54 nano-coated waterproof LED strips are two popular choices.

This article will explore the key differences between these two types of LED strips in terms of appearance, waterproof performance, production process, and usage advantages , helping you make an informed decision for your lighting needs.

Exposed PCB (Printed Circuit Board) with visible LED chips and circuitry.

No protective coating, leaving components vulnerable to dust and moisture.

Lightweight and flexible, suitable for indoor use.

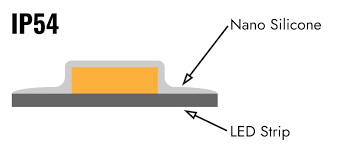

Nano-coating protection applied to the PCB, covering LED chips and solder joints.

A thin, transparent layer that does not affect light output.

More durable surface, protecting against dust and light water splashes.

No waterproof protection —susceptible to moisture, dust, and oxidation.

Suitable only for dry indoor environments (e.g., under cabinets, coves, decorative lighting).

Not recommended for areas with high humidity or potential water exposure.

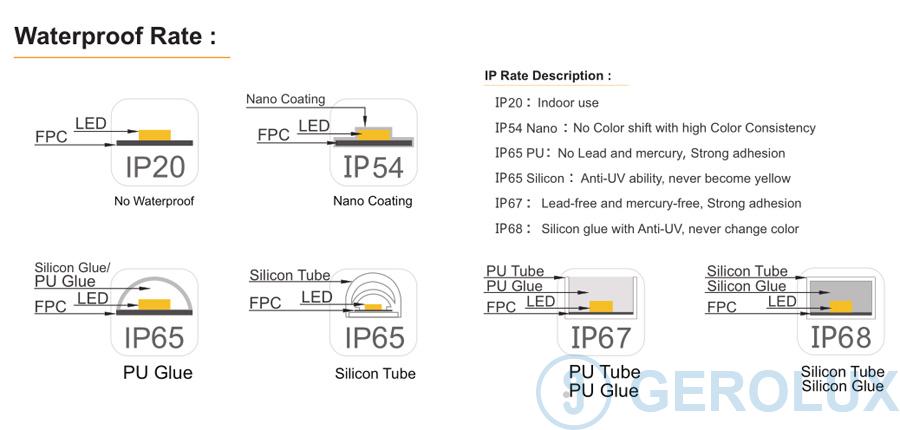

Water-resistant —can withstand light water splashes and humidity.

Dustproof (IP5X rating) and protection against low-pressure water jets (IPX4 rating).

Ideal for kitchens, bathrooms, garages, and outdoor areas where minor moisture exposure occurs.

Direct assembly of LEDs and components on the bare PCB.

No additional sealing process , making them more cost-effective.

Requires careful handling during installation to avoid damage.

Nano-coating application after standard PCB assembly.

Specialized waterproofing process : The PCB is dipped or sprayed with a nano-sealant that forms a protective layer.

Higher durability due to the coating’s resistance to humidity and minor water exposure.

4. Usage Advantages

IP20 Non-Waterproof LED Strips

✔ Lower cost —economical for large-scale indoor projects.

✔ Better heat dissipation —bare PCB allows for efficient cooling.

✔ Easy customization —simple to cut and solder for specific applications.

No previous NEXT:What's the Enki LED Strip

Contact: Elva

Phone: 86-18875928607

E-mail: elva@gerolux.com

Whatsapp:8618875928607

Add: Liyuan Industrial Park Shiyan Town Baoan District Shenzhen China

We chat